Orsha Aircraft Repair Plant OJSC - move up! Happy birthday to the factory!

Orsha Aircraft Repair Plant OJSC - move up!

Dear veterans and workers

Orsha Aircraft Repair Plant OJSC!

Colleagues! Friends!

Today we celebrate the birthday of our factory!

Over 79 years, many generations of aircraft repairmen and their home places have changed, but the traditions of faithful service to the chosen business and profession, responsible attitude to official duties and high-quality repair of aviation equipment laid down by our senior colleagues remain the same. The best confirmation of this is our movement towards improving the material and technical base and social sphere of the plant, mastering new types of repair and manufacturing of aircraft components.

Today, at a difficult time in the market of aircraft repair services, we manage to ensure the loading of the enterprise at least at a level that allows us to consistently pay wages and maintain staff potential. In this case, all possible measures are taken to search for customers and potential customers.

On this festive day, accept deep gratitude for your diligent work, high professionalism, understanding of the current moment and our best wishes for good health, happiness and prosperity to you and your families!

I sincerely wish you optimism in life, warmth and comfort in your homes, loyal and reliable friends, a clear cloudless sky in life!

Happy holiday to you! Happy birthday to the factory!

Administration

The development, modernization and development of new technologies of JSC “Orsha Aircraft Repair Plant” today is carried out in the framework of the implementation of the Decree of the President of the Republic of Belarus dated December 31, 2018 No. 506 “On the Development of the Orsha District of the Vitebsk Region” and Decree of the Council of Ministers of the Republic of Belarus dated January 28, 2019 No. 58 “On approval of a set of measures to implement the Orsha District Development Program for the period up to 2023”, Measures for the implementation of the Industrial Complex subprogram “Set of measures for the implementation of the Orsha Region Development Program for the period until 2023” Task 12 “Modernization and ensuring volume growth industrial production at Orsha Aircraft Repair Plant OJSC and RB "Development Programs of Orsha Aircraft Repair Plant OJSC for 2018-2023 approved by the State Committee for Military Industry".

The main directions of investment policy of JSC

"Orsha Aircraft Repair Plant" for 2018 - 2023 and until 2030 are:

- optimization of production capacities and involvement in

economic turnover of unused and inefficiently used

property;

- modernization and updating of the material and technical base in order to

expanding the range of work performed;

- development of the social infrastructure of the plant and giving a favorable appearance to the territory of the enterprise.

The development of the enterprise is in full accordance with the above listed guidelines in the following main areas:

- in order to optimize production facilities, systems

heating, power supply and technological movements

the construction of a universal production building has begun, which includes a unit repair area, an electrical equipment repair area, a mechanical section, a galvanic section, as well as an administrative household building in one production building in territory No. 1;

- technological re-equipment of the above listed areas, the acquisition of new, modern equipment, including CNC;

- work is underway to develop a project for the construction and equipping of a repair site for the main gearboxes;

- re-equipment of the central factory laboratory (TsZL) and the department of the chief designer (OGK);

The acquisition of new modern high-performance equipment with high precision characteristics will allow further localization of the manufacture of parts for mandatory replacement and bring it to a level of at least 90% and reduce the repair time of aircraft by 35%. Due to the optimal modes, low energy consumption of modern equipment, reduction of material consumption standards, material costs will be reduced by no less than 25%.

To date, purchased:

- equipment for the manufacture of hoses and pipelines, which will exclude the purchase of rubber hoses of low and high pressure on average in the amount of $ 27,000 (Mi-24) / $ 11,000 (Mi-17) for 1 helicopter. CNC equipment for pipelines will make it possible to manufacture a pipeline of any configuration and minimize purchases;

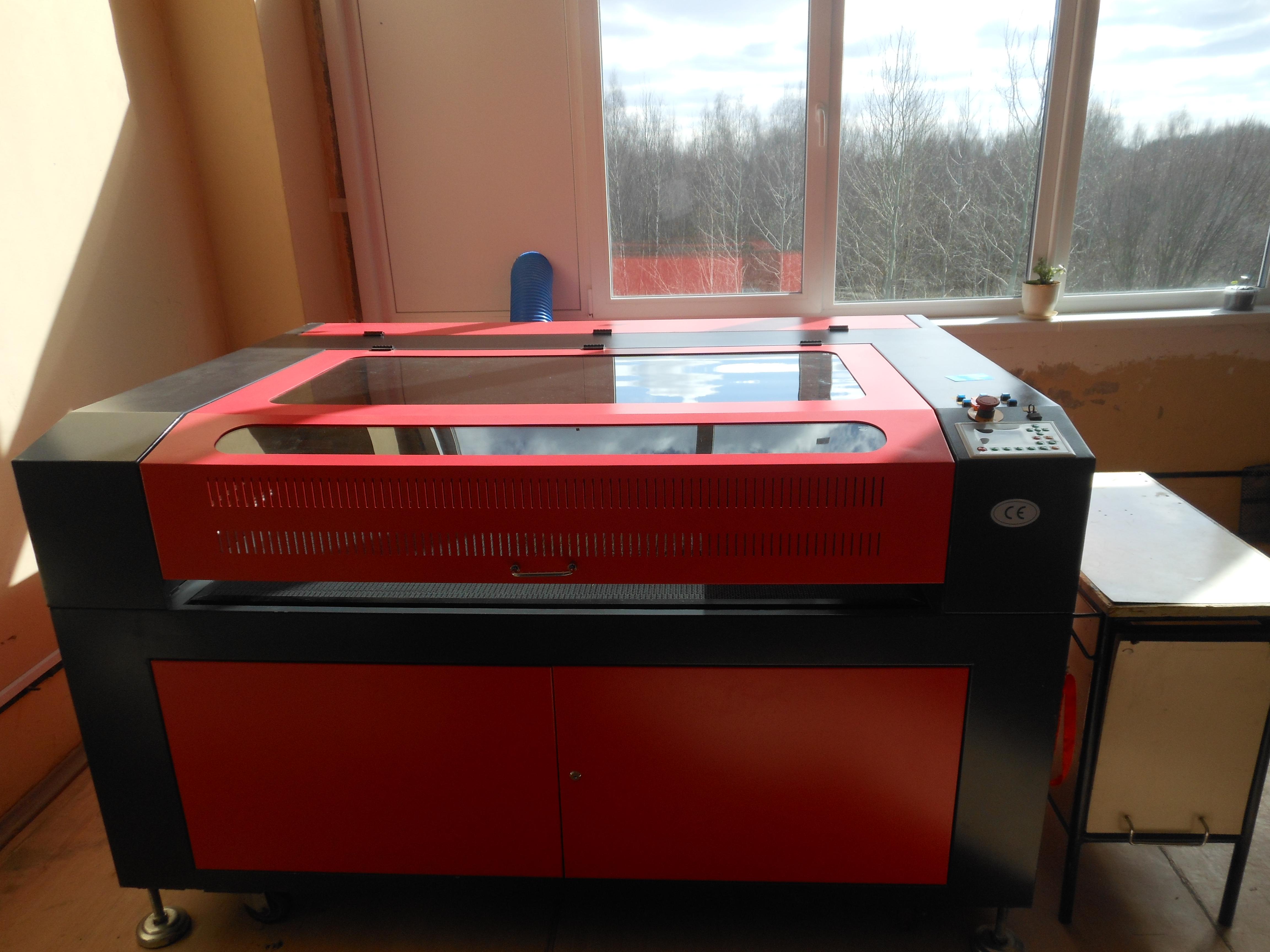

- CNC equipment for laser cutting, welding and surfacing, which made it possible to expand the range of parts of our own production and to restore the dimensions of parts after defection;

- vertically milling CNC machining center, which allowed to expand the technological capabilities of the plant to master the manufacture of parts for mandatory replacement in the repair of aircraft;

- 5 pieces of universal especially precise turning screw cutting machines of type 250ITVM.F1, which allowed updating the park of metalworking equipment with improved accuracy characteristics, and as a result, improving the quality of products;

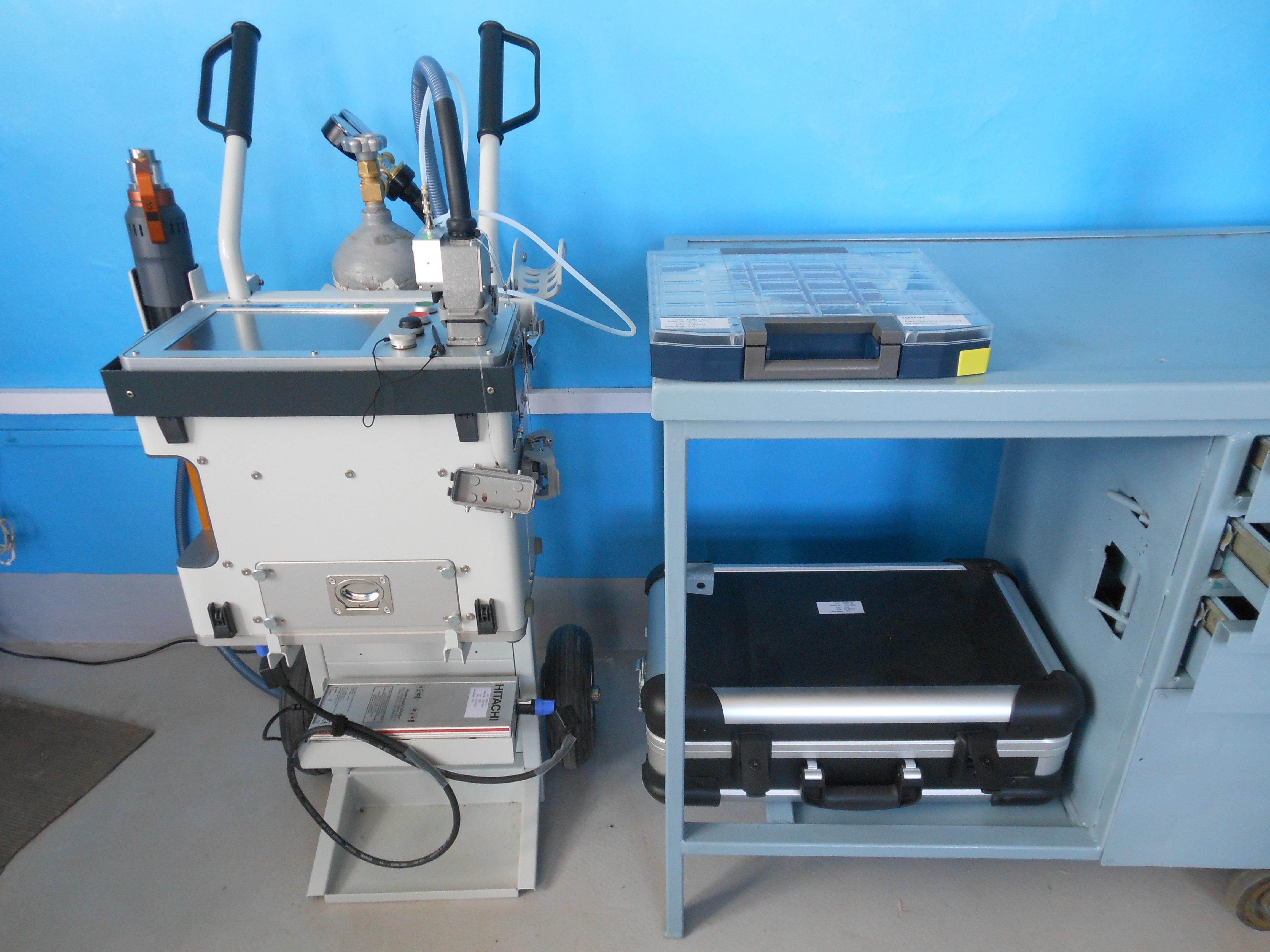

- Digital video endoscope, which provides the necessary quality control of products having internal cavities (engines, tanks, cylinders, pipelines), as well as photo video control of components after repair;

- Vector circuit board troubleshooting system, which will provide troubleshooting and troubleshooting of electronic circuit boards;

- equipment in the form of heated rollers, rubber calender, hydraulic press, for the area of rubber products (RTI), which will increase the range of RTI own production;

- bench equipment for testing, refueling and testing various systems of helicopter technology;

A modern testing equipment (9 items) in the form of PMI-Master-Smart was purchased for the central laboratory - for the analysis of chemical elements in metals and alloys, explosive machines, etc. - in the amount of over 270 thousand rubles;

For OGK purchased - a work graphic station, personal computers and software. Purchased software: SolidWorks computer-aided design system (two network licenses), SolidCAM system development program for CNC machine tools (2 network licenses), Intermech design automation system integrated into SolidWorks with CADMECH 3D and AVS modules (six network licenses )

An Intermech automated technological training system was purchased for technologists, with TECHCARD and LCAD modules (three network licenses). All jobs of process engineers are computerized and an automated system of technological preparation of production Intermech was acquired, with TECHCARD and LCAD modules (three network licenses) - for a total of more than 308 thousand rubles.

Expanding the range of products being repaired will allow the company to be competitive in the conditions of continuous modernization of nuclear power plants, operation of new modern units and avionics systems (aviation and electronic equipment), the introduction of new methods of operation and maintenance (repair) of modern (imported) equipment (operation by technical condition, operation to safe failure). Fulfillment of the planned work will reduce the repair time for aircraft, participate in the repair of units for other enterprises, and reduce export dependence.

In 2019-2020. close attention was paid to the development of the social infrastructure of the plant and giving a favorable appearance to the territory of the enterprise. In July 2019, reconstruction of the hostel No. 2 (57 Gritsevets St.) was completed, the appearance was updated and replaced with plastic windows of the administrative building and hangar No. 2,

- diseased trees along the access road from the main checkpoint to the EMO were removed and about 1000 ornamental plantings were planted,

- Almost newly built car parking for personal transport workers.

The facades of many buildings and structures were updated and given a modern look, the laboratories and production sites were repaired.

In April, at the republican subbotnik on 25.04.2020. employees of the household department planted 20 fruit trees at the checkpoint, and plant managers from the master and to the general director planned the territory at the EMO and planted 20 blue spruce trees and 16 ordinary pine trees.

Upon completion of all planned activities, we will receive a virtually new factory for the repair, modernization and maintenance of aircraft.

Dear veterans!

We remember your contribution to the establishment, preservation and development of our plant, we preserve and continue these traditions today. Happy holiday to you!